EF Johnson Viking 500 #2 - RT's Radio Home Page

Main menu:

EF Johnson Viking 500 #2

Amateur Radio > Vintage Transmitters

The latest project is yet another Viking Five Hundred. This unit was a real challenge because no power supply/modulator unit came with it. The consensus regarding why there are so many orphaned RF units around is due to families of amateur operators who have passed on have no clue that the big, heavy box on the floor is a neccesary component related to the transmitter unit on the desk. (Credit: Rodger, WQ9E). The units become separated, and the power supply will go a different direction than the RF deck.

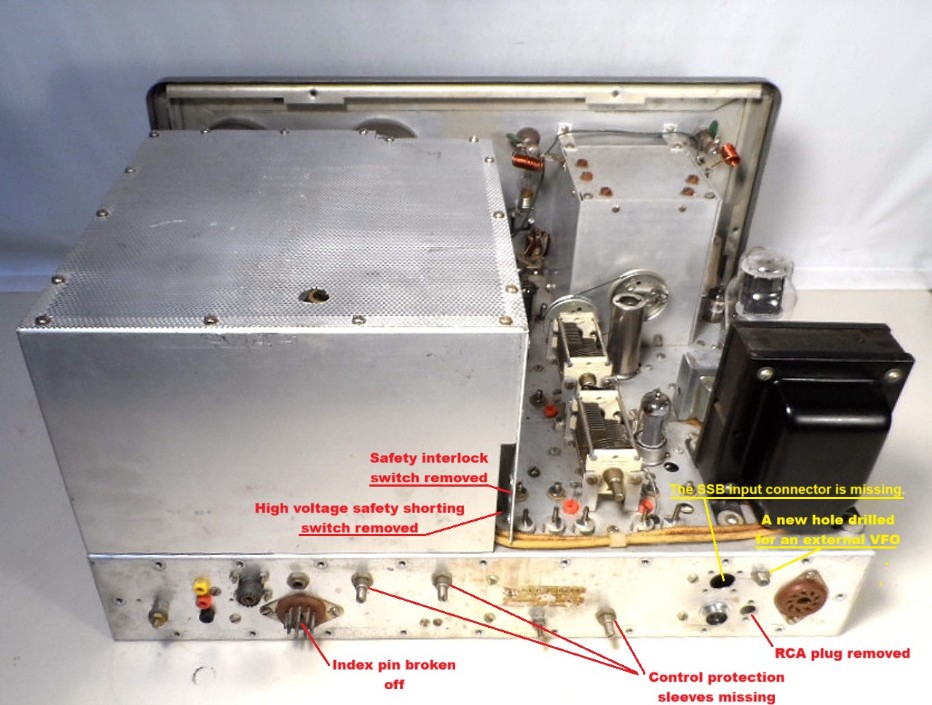

This Viking Five Hundred has been restored on the exterior and was nicely done; in contrast however, it was an electrical challenge on the interior. Strange modifications, circuits removed and others added. The first find was a hard-wired short on the 120 volt line; four damaged switches, and the VFO board had burned due to the "chernobyl" 18K resistor. After replacing the VFO board, repairing the switches and removing the non-original wiring and restoring the missing circuits, the RF unit more or less worked.

Rear view of the transmitter as found. It makes no sense why someone would remove an existing RCA jack then drill a hole for a new RCA jack right above where the other one was removed.

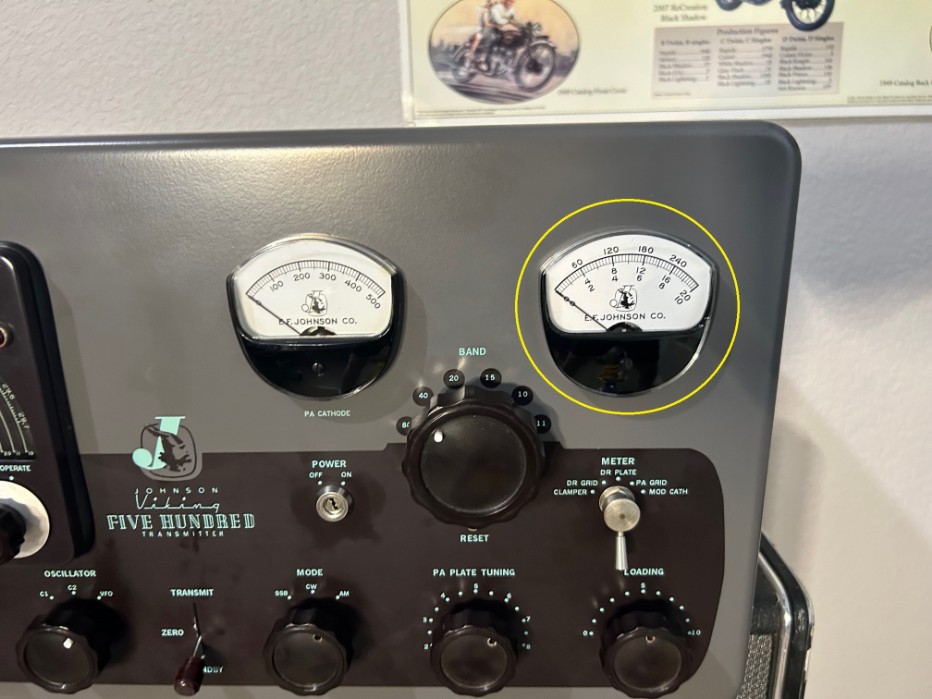

July 2025: After many hours of locating/removing useless modified circuits including a dead short, locating/replacing deleted circuits, finding and re-facing the multi-meter, finding, shunting and re-facing the cathode current meter, rebuilding the burnt VFO and repairing the audio section, the RF deck is airworthy again. It easily does 300 watts using its old JAN 4-400A.

Metering:

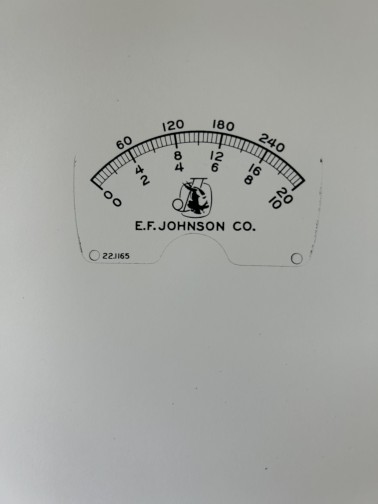

Here is the original multi meter. The face had been reproduced on cheap copier paper. It needed replacement.

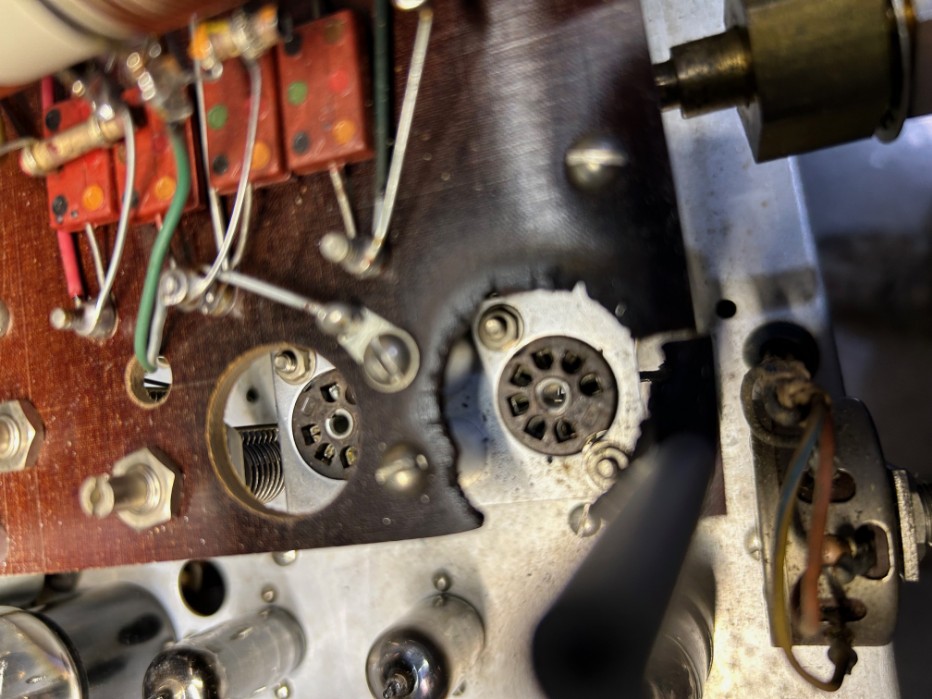

The VFO had suffered from the degredation and failure of the infamous 18K resistor. In this case, the resistor must have shorted during the meltdown causing the 0A2 regulator tube to overheat and literally burn the phenolic VFO platform.

In Viking Ranger and Valiant transmitters, it would have been easy to replace the entire VFO unit from a donor transmitter; however, the Viking 500 is slightly different as its VFO also provides the mechanical drive for the auto-tuned RF stages. Ranger and Valiant VFO's lack this drive system.

The best solution was to replace only the phenolic board which carries the VFO coil and variable capacitors; this donor board came from a Viking Valiant parts rig. The 0A2 socket was also replaced due to damage by the overheating of the 0A2 tube. It was a labor-intensive undertaking, and the outcome was worth the effort. At this point, the 6AU6 was replaced by a 6AH6 as advised by WQ9E. The repaired VFO works very well, and stability is excellent.

The panel meters:

The meters supplied to EF Johnson were produced by "Marion". A nearly identical unit is sold under the "Honeywell" brand, but few parts are interchangeable. Initially, the meters seemed OK, though the Cathode Current meter (left) suffered from maroon paint peeling on its interior.

Multi-meter: Once the RF unit was ready for testing, the multi-meter (right) was sluggish in movement and was sticking in position. Close examination revealed the meter face was a photocopy on cheap paper, and fibers of the paper were obstructing the needle. The paper was also yellowing, so it had to be replaced. Inspecting and testing the meter, it is made by Honeywell and is electrically incompatible with the Viking 500. Fortunately, I have a Viking Valiant parts rig, and the Valiant meter tested identically to the good multi-meter in Viking 500 #1 except the face was the wrong scale.

Disassembling and removing the original meter face from Viking 500 #1, the local Fedex/Office staff made copies of that meter face on premium cardstock. Cutting out the new meter face was straightforward; however, without an accurately sized hole punch, creating the alignment holes in the new face to accept the locating dowels on the meter body proved difficult. The solution was creating the holes by carefully burning them out using a long-tapered soldering tip. 3M #77 spray adhesive was used to attach the new face to the metal face backing plate.

The bezels of the meters were originally colored in the standard Johnson maroon. For whatever reason, the Cathode Current meter had been painted to match; this paint was flaking off the inside of the meter. The only matching bezels I had on hand were black Honeywell bezels; these do fit Johnson (Marion) meters, so they were installed.

500 mA Cathode Current meter:

Once the transmitter was in operation, it became clear this meter was reading incorrectly. It was reading about 30% low. Given the readings, this is likely a meter from a Viking Thunderbolt amplifier meter refaced with a 500 mA scale. A 100 mA Marion meter was found on the 'bay", and an external shunt was added. It now reads 500 mA at full scale and is spot-on with a known accurate 500 mA Tripplett meter.

After opening and swapping parts for Various Johnson meters, I suspect they all have the same rated movements. F.S.=5 mA? So far, the meters found in the higher powered gear are internally shunted. Meters for the Valiant and Ranger are all externally shunted at the circuits they serve.

VFO Burnt by Chernobyl Resistor

The VFO had suffered from the degredation and failure of the infamous 18K resistor. In this case, the resistor must have shorted during the meltdown causing the 0A2 regulator tube to overheat and literally burn the phenolic VFO platform.

In Viking Ranger and Valiant transmitters, it would have been easy to replace the entire VFO unit from a donor transmitter; however, the Viking 500 is slightly different as its VFO also provides the mechanical drive for the auto-tuned RF stages. Ranger and Valiant VFO's lack this drive system.

The best solution was to replace only the phenolic board which carries the VFO coil and variable capacitors; this donor board came from a Viking Valiant parts rig. The 0A2 socket was also replaced due to damage by the overheating of the 0A2 tube. It was a labor-intensive undertaking, and the outcome was worth the effort. At this point, the 6AU6 was replaced by a 6AH6 as advised by WQ9E. The repaired VFO works very well, and stability is excellent.

To recap, I picked up this orphaned Johnson Viking Five Hundred RF Deck in early 2025. It is beautifully refinished/re-screened on the outside, but inside, a nightmare of mods/changes were found. Thankfully, most of the original main components were in good shape. I am a vacuum tube radio enthusiast and not an engineer, and I estimate having about 60-70 hours into this transmitter testing, pondering, re-wiring, repairing, etc. to get it back to the original schematic.

Fast forward to July 2025, using the power supply of Viking Five Hundred #1, the transmitter is alive again and transmitting at full power. Audio was borderline acceptable but is now clean after finding a bad capacitor in the audio circuit. It had been “re-capped” in the past, and the quality of that particular work is good. Judging from the capacitors used, it was likely done in the 1990’s; given the age of the replaced electrolytics, these were changed out for this build. The audio is now excellent.

November, 2025

Chuck, K1TLI is having a batch of new power supply chassis made, so a deposit was sent. His plan is to have them done before 2026.

First on air contact: First contact/QSO on using this transmitter was with a ham whose opinion I trust. He indicated the audio was excellent.

Fine tuning the clamper circuit controlling the screen voltage of the 4-400A final amplifier tube resulted in the Tune mode working properly and cooler running of the 4-400A.

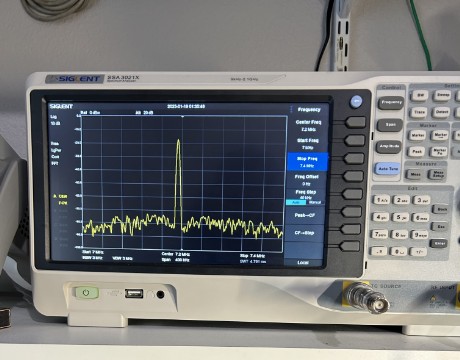

Unable to reach the Half Moon Bay KFS SDR to check audio. However, propagation did reach the Northern Utah Web SDR #1. Audio sounds good and clear.

Late December 2025: The new chassis is here! This required a lot of work by K1TLI to re-create this nickel-plated chassis.