EF Johnson Viking 500 - RT's Radio Home Page

Main menu:

EF Johnson Viking 500

Amateur Radio > Vintage Transmitters

The E.F. Johnson Viking 500 transmitter was produced during the late 1950s through about 1964; it runs both AM and CW modes. This is a photo taken shortly after bringing it home. Sources indicate production of the Viking 500 was limited to 865 units, so it is fairly rare. The transmitter employs an Eimac 4–400A tetrode tube in the RF final; modulation is provided by a pair of RCA 811A's.

In 2022, I decided to get a plate-modulated AM station up and running again. A couple of long-suffering Viking Rangers came home first. In January 2023, I found the Viking 500 above on Craigslist. I quickly contacted the owner and met with him. He had other rigs to sell, so a few more boatanchor rigs came home as well.

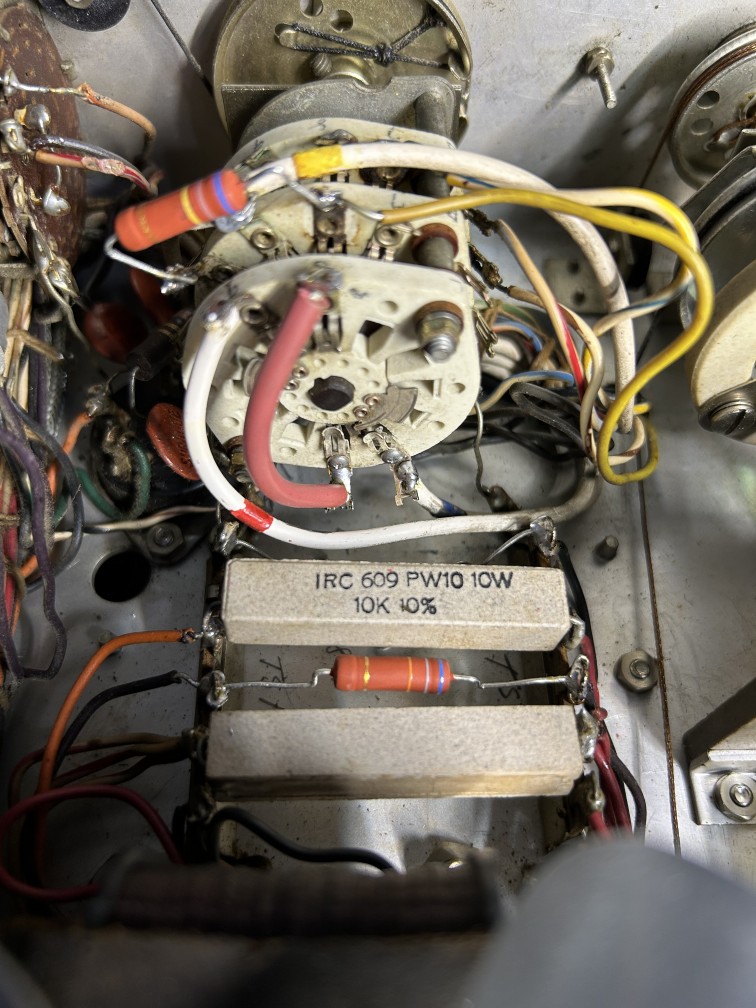

The underside of the power supply as found.

This is the completed power supply, underside of the chassis.

The major change/mod is the use of radial lead capacitors for the high voltage instead of those with axial leads.

The rationale for not using axial lead capacitors:

1: They are very expensive at $30+ each.

2: The radial lead capacitors installed are around $4.00 each and have better ratings, including longevity.

The new capacitors are lightly clamped into place by a square-sectioned plexiglass rod; radiused notches were cut in to cradle the capacitors. The notches are felt-lined, and there is a strip of felt under the capacitors. The leads are sleeved with insulation from 5KV test lead wire. The assembly is held in place by three longer screws with standoffs to limit clamping pressure.

The other mod is the delay circuit for relay RY302 which sequences the release of that relay to prevent arcing. No arcs have occured. (Thank you WQ9E!)

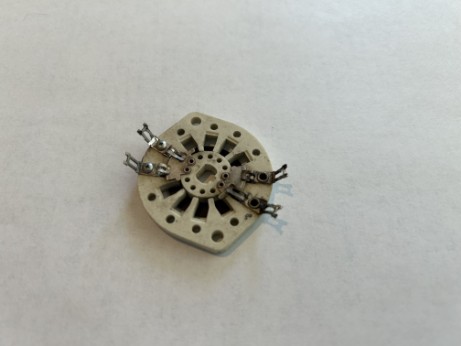

Here is a high-voltage switch under the chassis in the Viking 500. The lower pair of contacts had burned away. Thankfully, the rotor contact was un damaged. I’ve seen other Viking 500's in this condition, so it must be a fairly common occurrence. This section of the switch is made up of two completely separate sets of identical contacts that are actually wired in series with each other apparently to provide a wider gap to prevent arcing. Hot switching may have initiated the arc damage.

Here is the switch after making repairs. The replacement contacts were sourced from a donor Johnson Viking Ranger.

The repaired switch reinstalled.

I had paint mixed to match the E.F. Johnson Maroon. The 500 Case needed repainting as does most of my Johnson Viking gear. Here it is just after painting. The front rim of the Johnson Viking case is intentionally left unpainted to make electrical contact with the front panel. This is necessary to assure a good, RF tight enclosure. This case is masked off at that location.

I brought the Viking 500 home in January 2023. Here it is May 16, 2023, and the power supply top and bottom covers are finally back on.

Here is the finished Viking 500 in the shack.

The Viking 500 Power Supply. The power supply alone weighs in at about 120 Lbs. This is the main reason it is on a cart under the desk, on the floor.

The 811A's glowing in the background assist the other tubes in this transmitter in heating the shack in the wintertime.

Johnson Viking 500 Startup:

This transmitter had been stored in unfavorable conditions for many years; the rusted power supply chassis indicated moisture had been present. After many weeks of work on the 500, it was finally time to fire it up. Well, hopefully fire would not be involved! At first, the High Voltage fuses were left out, and it was energized only on the low voltage circuits. The filaments on the tubes lit up normally, the panel lamps came up, and the fan whirred along nicely. I ran it like this for several hours.

High Voltage testing: I’d never thrown the switch on a Viking 500 and didn’t know what to expect; the memory of users claiming arcs and sparks were unsettiling. Re-installing the HV fuses, I hesitantly turned on the keyswitch. Immediately, a sharp snap and loud buzz accompanied the lighting of the 811A filaments—I quickly shut it down! The sound was from a relay in the power supply that was merely mis-aligned. The relay aligned, the next test started out fine—a smooth startup! Again, I let it cruise for an hour or so before keying up.

The first key up: After going through the manual and setting all controls for the band selected, I finally got the nerve to key this beast up. Gripping the D-104 microphone, a click resulted but no response from the transmitter—no high voltage! My heart sank; is this a bad high voltage transformer? Opening up the power supply, the HV transformer has continuity on the primary and secondary windings. Further tests showed no voltage is getting to the HV transformer primary. The culprit was the relay serving the HV transformer was not making contact. Some massaging of the contacts, and all is ready for testing again.

The second key up, we have high voltage! Now it was time to check to see if my worst fear would be realized: the condition of the modulation transformer. I keyed up and tuned up to 100 watts. Slowly turning up the audio control, I tested the microphone. We have audio. The modulation transformer is good!

Retuning, I found the transmitter will produce 300 watts of plate modulated AM. Testing on the air, it is a very smoothly operating transmitter and gets good audio reports.

This entire project has been worth every hour and dollar invested.

Modifications:

1. The infamous 18K "Chernobyl" resistor in the VFO has been changed to a 20K, 5 watt version. The original resistor is attached outside the VFO cage to show it hasbeen replaced.

2. The 6AU6 in the VFO was replaced with a 6AH6 as advised by WQ9E.

3. The 866A's were removed and replaced with a pair of 3B28's.